Our production sites based in Cloppenburg, Kaufungen and Cologne operate in shifts. They process typical raw materials to produce biodiesel. We pay great attention to the feedstock used, which mainly consist of residual and waste materials according to the biofuel sustainability regulation. This helps us produce biodiesel that only requires a minimum of fresh vegetable oils.

We use the raw materials we use to produce our sustainable and climate-friendly biodiesel in accordance with DIN EN 14214. In addition to the production of biodiesel, we also produce glycerins of various qualities.

The continuous monitoring of the entire production chain is carried out by our company laboratory and we thereby ensure the consistently high quality of our products. Qualified employees continuously check all process-relevant parameters for product quality and compliance with the standards.

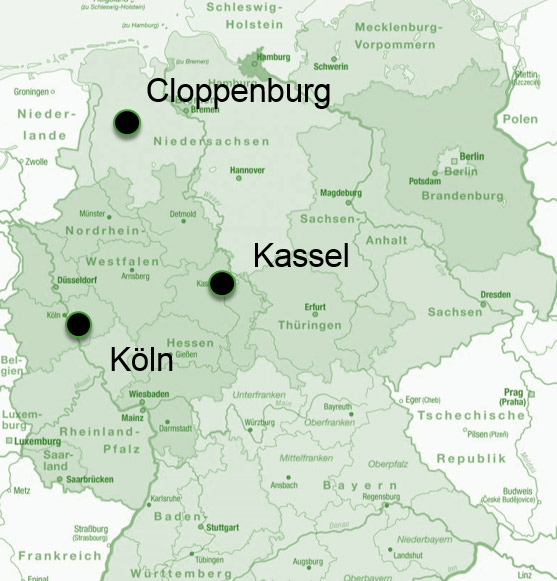

KFS Biodiesel sites

Great transport links ensure speed and flexibility

The accessibility of our Cloppenburg, Kassel and Cologne sites enables KFS to meet customers’ demands with great speed and flexibility. Great transport links ensure truck delivery and maritime transportation. All production facilities can use vegetable oils, waste edible fats and animal fats as feedstock to produce biodiesel.

You can reach us here!

KFS Biodiesel GmbH & Co. KG

Industriezubringer 3

49661 Cloppenburg

GERMANY

Telefon: +49 (0) 44 71 / 18420-0

Telefax: +49 (0) 44 71 / 18420-220

E-Mail: info@kfs-biodiesel.de

Cloppenburg site

KFS Biodiesel GmbH & Co. KG, Industriezubringer 31-35, 49661 Cloppenburg / GERMANY

Operations Management: Mr. Thomas Cloer and Dr. Olaf Broxtermann

Phone: +49(0)4471 18420-214 and -213

Our biodiesel production facility based in Cloppenburg is a multi-feedstock production plant processing vegetable oils, animal fats and waste edible fats from the catering industry. This site is located in the industrial area of Cloppenburg, which has a direct access to the national B72 motorway.

It is very easy to get to Cloppenburg due to excellent transport connections. The national A1 (“Hansalinie”) motorway runs east (exit 63). And it is only a 15-minute drive to reach the A29.

The national B69 motorway runs from the Cloppenburg exit to Diepholz. The B72 links Cloppenburg to the North Sea coast (“Norddeich”). The B213 links Delmenhorst via Cloppenburg to the Netherlands. Cloppenburg is the crossing of the B72 and the B213. These two roads join to become a bypass similar to a well-developed motorway.

The western terminus of the four-lane bypass in Cloppenburg uniting the B72 and B213 becomes the B68 running south (“Quakenbrück/Osnabrück”).

Biodiesel: 50,000 tons of a year

Glycerol: 4,500 tons a year

Tank trunk loading

Raw material intake by tank trunk

2,000 tons of total storage capacity for biodiesel and different feedstock

Kassel site

KFS Biodiesel Kassel GmbH, Schwarze Breite 15, 34260 Kaufungen / GERMANY

Operations Management: Mr. Andreas Vellmete Deputy: Mr. Edin Zilic

Phone: +49(0)561 2075665-15

Our biodiesel production plant based in Kassel / Kaufungen is a multi-feedstock facility processing vegetable oils, animal fats and waste edible fats from the catering industry. This site is located in the industrial area of the Kaufungen paper mill, which has direct access to the A7 motorway.

It is very easy to get to Kaufungen due to excellent transport connections. The national A7 motorway (Hannover-Kassel-Würzburg) runs west of Kaufungen (exit 78), the national A44 motorway (Kassel-Dortmund) is only a few minutes drive away.

The national B7 motorway starts at the motorway exit 78 (Kassel-Ost) running east and continues to Eisenach, Erfurt, and Gera. The B252 links Kassel/Kaufungen to the west. It continues to the Sauerland region. The B83 runs north and takes you to Hameln and Bueckeburg. It continues via the B65 to the A1 (“Hansalinie”)

Biodiesel: 50,000 tons of a year

Glycerol: 5,000 tons a year

Tank trunk loading

Raw material intake by tank trunk

1,000 tons of total storage capacity for biodiesel and different feedstock

Cologne site

KFS Biodiesel Köln GmbH, Feldmühle 3 (Evonik Chemiepark Lülsdorf, building 519), 53859 Niederkassel / GERMANY

Operations Management: Mr. Philipp Brettschneider / Deputy: Mr. Marco Lück

Phone: +49 (0) 2208 76869-13

Our biodiesel production plant based in Cologne is a multi-feedstock facility processing vegetable oils, animal fats and waste edible fats from the catering industry. This site is situated on the right bank of the Rhine River in a chemistry park covering an area of 100 ha between Cologne and Bonn right at the Rhine River.

The Rhine waterway

Our biodiesel plant is located close to one of the world’s busiest waterways. So the operator benefits from direct access to the North Sea and the European inland waterways network. This site has direct pipeline access to maritime transport, loading and unloading tankers of up to 5,000 GRT. These are major logistic and economic advantages turning this site into an import/export hub.

Motorway access

There are well-developed bypasses that help you reach the motorways in no time, which is only 7 km away.

Biodiesel: 120,000 tons a year

Glycerol: 12,000 tons a year

Fatty acids: 5,000 tons a year

Ship loading

Loading tank trucks using three tanker loading lines

Raw material intake by tank trunk or maritime transport

Rail network situated at the site

9,000 tons of total storage capacity for biodiesel and different raw materials